It appears there are renewed fears for an increased fragility of supply chain networks in the face of continued catastrophic natural disasters and or sudden shifts in macro-economic conditions. Unexpected cost structures can arise where a business fails to put in place a robust risk mitigation plan to cater for supply chain disruptions.

As the scale of the procurement department increases in scope, size and complexity, so too does the supply chain risks. It is undeniable that when supply chain professionals buy from suppliers often scattered throughout the world, supply chain-related risks are their ever-present companion.

To put it in simple terms, supply chain risks lurk in every corner of procurement. It is an apt analogy of today’s business environment. The world presents an ever-growing area of vulnerability for the supply chain. To achieve a high level of distinction, procurement requires the delivery of exceptional value by utilising procurement risk reduction strategies in every facet of the business.

Procurement risks can come in all shapes and sizes. Supply chain professionals must always ensure that they stay informed about the latest market trends, geopolitical effects, natural disasters, economic instability, supply chain disruptions and ever-changing technological improvements.

Other common problems across all industries and markets include depressed consumer demand, uncertain demand outlook, tighter liquidity, commodity price volatility, global recession and shifting markets.

Supply chain professionals are required to live with the constant realisation that these supply chain challenges could strike unexpectedly without notice. They will be required to proactively navigate the inevitable uncertainties in the operating environment. Within the supply chain profession, there is obviously no illusion over the level of vulnerability that the business is likely to encounter in the event of supply chain disruptions or the potential drawbacks that come with such challenges as short supply or no supply.

Supply chain risks can result in financial losses, operational disruptions, unnecessary delays and reputational damage. Procurement leaders must be ready to deal with the supply chain risks no matter what the world throws into their path.

Due to the continued occurrence of catastrophic disasters, businesspeople, the world over, are slowly coming to terms with the fact that it is no longer business as usual. Companies are therefore realising the need to ensure that the gap between risk identification and mitigation should not be as wide.

- Emotional intelligence imperative in supply chain management (II)

- Cost to serve analysis: The holy grail of profitability (I)

- Cost to serve analysis: The holy grail of profitability (11)

- Increased focus on supplier diversity is the way to go

Keep Reading

Following this realisation, it stands to reason that procurement practitioners must come up with various supply chain visibility strategies which enable them to prepare for risks. Procurement must take a leading role in coordinating the dissemination of information on supply market trends to other cross functional teams.

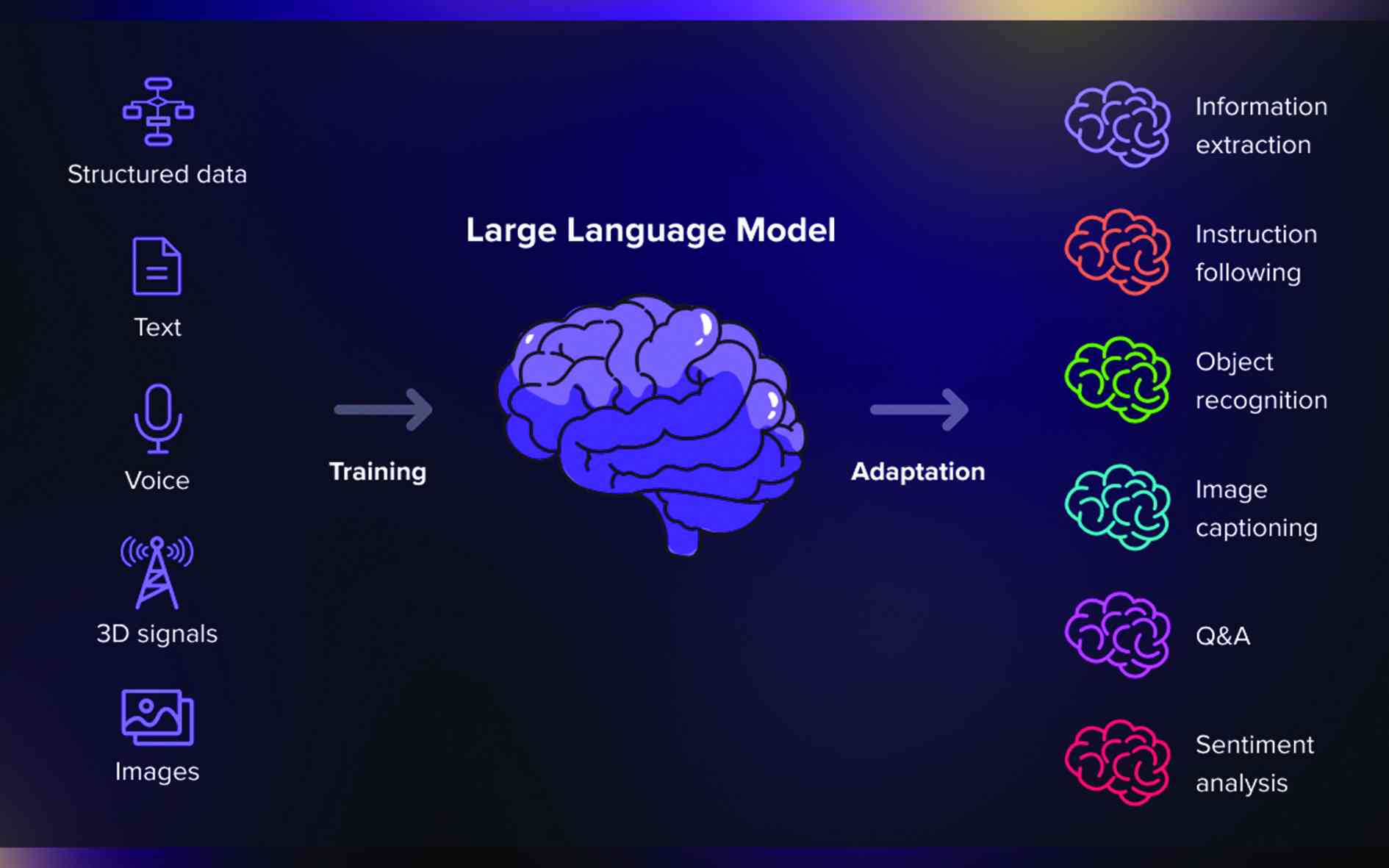

The current supply chain landscape indicates that those macro-economic winds of change will continue to blow worsening the volatility of supply markets. The upsurge of new forces being created by the proliferation of social media, daily scientific discoveries and the emergence of artificial intelligence is compounding the supply chain risks. Such developments can have and will have a significant impact on the risk of supply.

With this in mind, best in class companies are very quick to find ways to use time as a competitive advantage by being able to react faster than the rest of the pack whenever there is an occurrence of supply chain disruption. This can only happen where procurement keeps itself abreast of supply market trends and developments and shares the same with other internal customers as and when they happen or just before they happen.

Experience, over the years, has demonstrated that supply chain risks are an ever-evolving threat and conducting scenario planning exercises may assist in the identification of potential problem areas without significantly delaying or affecting production timelines.

Procurement should not be sitting on the sidelines watching the supply sources of the business dwindling without taking any action. They should be seen to be in the middle of action influencing major risk management practices by ensuring that the organisation’s supply sources are continuously widened by introducing new players while periodically reviewing the performance of suppliers, past and current.

As part of risk management, procurement practitioners are now required to have a deeper understanding of the capabilities of their vendors and the vendor’s capacity to manage supply chain disruptions in the event of one occurring unexpectedly. By so doing, they will minimise disruptions while ensuring continuity in operations.

In this complex but opportunity rich environment, there is now a renewed management focus on crafting risk reduction and mitigation strategies by putting more emphasis on “what will or could happen rather than what did happen”. This will assist in taking a proactive posture to minimise risk.

As is often said, the era of plentiful supply is no more. To help the organisation navigate the future, procurement practitioners should be making business decisions based on evidence and analysis by monitoring economic developments such as commodity price indexes, inflation and general economic conditions on the ground.

In an attempt to prepare for unforeseen shifts in demand, procurement decisions should not be based on clairvoyance but on supply chain data monitors which provide demand side visibility through the use of cross functional corporate conversations between procurement, production and marketing.

To state the obvious, for procurement practitioners to stay ahead of the risk curve there is need to ensure supplier risk analysis goes beyond the first-tier supplier and extend to the supplier of the supplier or the customer of the customer. In some instances, procurement practitioners can mitigate supplier risk by putting in place a dual sourcing arrangement for key requirements.

However, without careful risk analysis it may turn out that both the first-tier supplier and the second-choice supplier may heavily rely on one downstream supplier for their inputs. In the event of supply chain disruptions on that one downstream supplier then the whole supply chain will break down.

Modern-day procurement practitioners could also continuously utilise the supply chain market peer network to share supplier risks, demand forecasts and general performance capabilities of certain suppliers before making any significant financial obligations. Generic information about supplier performance is obtainable free of charge from fellow procurement professionals because every supplier is the next company’s supplier or the next company’s customer.

Procurement practitioners across the industry divide must continuously share information on new exciting products on the market, substandard products, delinquent suppliers and those that are on the brink of bankruptcy.

Hackers can compromise the supplier’s systems, exposing confidential and sensitive information. It is therefore important to invest in robust cybersecurity systems. Conducting regular vulnerability assessments and implementing data security protocols can assist in providing a layer of protection. To minimise cybersecurity risks, it may be important to introduce encryption of confidential and sensitive information. It is increasingly important to avoid breaches that could disrupt the supply chain and damage the reputational integrity of the business.

To enhance more security, contracts are specifically meant to protect the organisation. Reliance on third parties relinquishes a degree of control to suppliers. Supply chain professionals are required to scrutinise every little clause in the contract with a view to ensuring that all terms and conditions are risk-free and to ensure nothing slips through the cracks. That’s a lot of boxes to tick. Supply chain professionals are required to ensure that performance metrics are well-defined and unambiguous.

It must also be noted that different countries have different regulations regarding labour laws, environmental standards and trade policies. Poorly-drafted contracts can expose your organisation to financial risks and legal liabilities.

It must also be noted that in this social media world order, there are increasingly highly empowered and well-informed consumers who make it their business to voice concerns even in matters that do not directly affect them. The situation is compounded by the fact that consumers the world over can easily share information at short notice through social media platforms.

In some instances, sharing product information is buoyed by environmental concerns bordering on too much enthusiasm which can significantly influence the uptake of company products either in a negative or positive way. Procurement should therefore only deal with those suppliers which are beyond reproach, otherwise they risk being dragged into social media wars.

While risks have always been around since the dawn of business, procurement will need to treat supply chain risk mitigation as a strategic imperative in order to ensure that there is always a protective wall around the business from the uncertainty and turbulence that is encountered from the ever-changing economic landscape. We are trading in an era that is pregnant with uncertainties. Think of your procurement risk management strategy as your business’s safety net.

The modern business landscape is a minefield of procurement risks. A robust risk mitigation framework can mean the difference between a good year and a great year. The organisation’s supplier’s actions reflect your reliability.

Your organisation is only as strong as your supply chain. These aren’t just theoretical concerns, they are daily realities. One doesn’t have to look very far to understand the dramatic impact of risk and compliance issues on the supply chain.

- Nyika is a supply chain practitioner based in Harare. — [email protected]