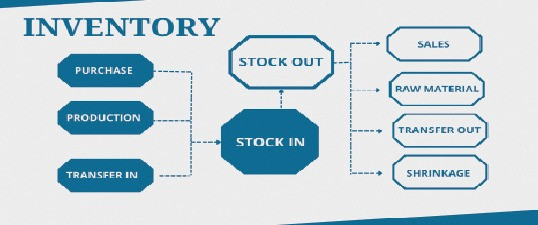

RUNNING an efficient supply chain system comes with countless challenges, but few are as persistent as inventory management challenges.

It has been established over the years that too much inventory ties capital together with warehouse space. While it is also true to say too little inventory often leads to stockouts and unhappy customers.

Organisations will be required to practice a serious balancing act to remain competitive. Managing inventory in a highly-volatile business environment can often feel like a relentless business cycle which brings little return.

Given the razor-thin profit margins, fluid demand signals and unpredictable consumption patterns, it is no wonder business leaders strongly feel the weight of business decisions made in inventory management.

Keeping track of inventory in an organisation can often feel like a juggling act. It is critically important because it helps organisations manage cash flows more efficiently by reducing capital investments in inventory.

In such a business environment, supply chain professionals will be required to embrace smarter inventory management strategies to stay ahead of the curve.

In most organisations, inventory is the biggest asset. Without proper management, this asset can easily turn into a huge liability, costing organisations dearly in both dollars and opportunity cost.

Organisations are often faced by challenges where inventory that may be necessary today may become obsolete tomorrow, and if that happens, their capital will be tied up in unused and useless inventory.

- The bookends to transformation

- ‘Road carnages now a pandemic’

- Emotional intelligence imperative in supply chain management (II)

- Cost to serve analysis: The holy grail of profitability (I)

Keep Reading

In the intricate and high-stakes environment of procurement, supply chains compete not so much through what they do but through how they do it.

Where organisations are impaired and fail to deliver products on time, customers may switch to competition.

Organisations are therefore required to step outside their comfort zones and retreat into their customer’s worlds, turning them into loyal advocates.

Inventory levels will be required to match and mirror the demand requirements of customers. Otherwise, consumers will be at the forefront of sanctions before the organisation knows it.

Amid these frenetic business challenges, organisations must be seen to be creating inventory models that are deeply resonant with the customer to remain competitive and future ready.

To achieve such an objective, supply chain professionals will be required to replace the traditional reactive stock control management process with a proactive, data-driven approach.

That is where vendor-managed inventory comes in as a solution. Vendor-managed inventory is a supply chain management tool where vendors are given the responsibility to take care of such activities as stock taking, product replenishment, inventory turnover management, and stock keeping.

The supplier will be accorded the full responsibility for the timely and accurate replenishment of inventory levels in line with the current customer demands. This inventory management model is most ideal where retail chains deal with high-volume, predictable demand items, where the benefits of streamlined replenishment process outweigh the complexities of using such a model.

It is also most viable when the cost of stockouts is significantly high, as it minimises the risk of lost sales and supply chain disruptions.

This model represents a significant deviation from a reactive, transactional approach to a more proactive, collaborative strategy that leverages data and analytics to drive decision-making.

The model allows suppliers to take the lead, ensuring that restocking is done timeously when product requirements hit predetermined thresholds.

Suppliers will be responsible for tracking demand and for the replenishment of stocks in sync with actual sales data. This will cut down instances of stockouts and surplus inventory.

Those suppliers that are committed to the management of inventory will typically take full responsibility for product lifecycles, minimising the chances of remaining with outdated stock.

This model allows stock to flow better as logistical shipments timing will experience a significant improvement, making it easy for the whole network to gain flexibility without losing control.

Vendors will carry the full responsibility of ensuring that inventory does not run out at any given point. The model hinges on real-time data exchange to optimise inventory management processes in an organisation.

It takes guesswork out of inventory management processes, ensuring that stock levels will stay optimised. Business leaders will stay laser-focused on what truly matters, which is growing the business.

They will be able to redirect their resources towards core business operations, such as production management and customer service.

It is often said that the backbone of any successful vendor-managed inventory system is the data that powers it. It has been established that where suppliers have access to detailed sales and inventory data of an organisation, they can rely on advanced analytics to predict future demand more accurately, leading to more efficient inventory planning.

The supplier will be responsible for monitoring the organisation’s inventory patterns, utilising a variety of scientific methods such as electronic data interchange, radio frequency identification, or barcode scanning.

Vendors or suppliers will be required to monitor inventory levels on a weekly or bi-weekly basis, set up minimum or maximum inventory levels, track usage, and optimise inventory levels at all material times.

The vendor-managed inventory model has the capacity to track key performance indicators such as inventory turnover ratio, order cycle times and demand forecast accuracy.

This will give suppliers the opportunity to observe and predict consumption patterns in near real-time, creating an almost symbiotic relationship with customers.

The system fosters a seamless flow of goods, allowing operations to continue smoothly without any manual intervention.

While every single member of the supply chain has perfect information about itself, uncertainties often arise due to lack of perfect information about other members. Using vendor-managed inventory will allow supplies to constantly share important information regularly.

All parties to the supply chain will benefit from the use of more accurate and timely stock updates and orders, lowering the chance of data input errors, miscalculations, and oversight errors.

Sharing information will provide a real-time picture of inventory levels at every supply chain node. The supply chain ecosystem will be better positioned to share inventory data, often through cloud-based platforms which will certainly provide the supplier with insights into current stock levels, sales trends, and upcoming demand forecasts.

In a vendor-managed environment, suppliers are in a better position to plan inventory needs and customer orders with clear visibility into current sales patterns, prevailing stock levels, supported by data-driven demand forecasting techniques. Supply chain professionals will therefore be able to shift replenishment control to suppliers, ensuring that optimal stock levels are maintained at all material times.

The demand information shared with suppliers will ordinarily include sales figures, stock withdrawal figures, production schedules, inventory levels, goods in transit and back orders, if any.

For all intents and purposes, the supplier, in essence, will be regarded as an extension of the customer’s supply chain and better positioned to meet customer needs on time, within budget.

The vendor-managed business model will give vendors the opportunity to utilise their expertise and market intelligence to come up with informed decisions about inventory levels, reducing the risk of stockouts and overstocking.

It works as an insurance package, where the supplier assumes the responsibility for inventory carrying costs and for delivering goods to warehouses and or retail stores. The common thread is the ultimate achievement of a more efficient, responsive and collaborative supply chain with competitive advantage.

The success curve of a vendor-managed inventory is a function of a collaborative approach, supported by good communication protocols, shared goals, and abundant data exchange. The collaborative partnership that is created will often result in preferred customer status during shortages – a critical advantage when products are in short supply.

The collaborative business relationships will promote an insider perspective which will allow suppliers to spot improvement opportunities invisible to outsiders. It gives supply chain partners the opportunity to apply their collective experience and intelligence, thereby creating a responsive and collaborative ecosystem.

Suppliers will also be best-positioned to decrease the amount of in-transit inventory in the pipeline and safety stock on hand, while also reducing the burden of slow-moving items. Suppliers are always better positioned to understand how to juggle around with demand for lead times.

This will facilitate the advance scheduling of production and logistics management of inventory. Vendors will be best positioned to ensure that customers have access to what they want and when they want it.

Suppliers will have more authority over their production schedules and distribution processes, leading to lower inventory carrying costs and less shrinkage while increasing the organisation’s fill rate and rate of return.

Vendor-managed inventory will generally assist in mitigating the bullwhip effect, where small fluctuations in demand can lead to larger variances in inventory levels up the supply chain.

Cash flow benefits of vendor-managed inventory extend beyond the obvious inventory reduction. Inventory carrying cost is the opportunity cost of capital invested in stocks along with the added cost of safety stock.

Financial resources will not be tied up in sitting inventory because there is no obligation to pay for inventory until it’s sold. The model allows for the withdrawal of inventory as needed and only pays for what is consumed.

This brings flexibility where organisations do not necessarily have to invest in inventory which they may not be able to sell to the market. It is therefore important to note that billing occurs after delivery rather than upon order placement, creating a more streamlined financial flow.

The resultant payment timing will align better with the actual usage patterns, minimising safety stock in the process. Safety stocks make a certain amount of money to sleep in inventory.

At the end of the day, keeping the end customers happy is what drives both the vendors and sellers’ business forward. The efficiency and the resultant reliability that is created will translate directly into customer satisfaction and operational stability.

The way the model is structured makes it a compelling choice for organisations striving to streamline their inventory operations with a view to enhance customer satisfaction levels. Happy customers often turn into advocates of your brand leading to organic referrals.

The business relationship between the organisation and suppliers will evolve from transactional to strategic. Suppliers will become invested in the success of the organisation, thereby creating benefits that extend far beyond inventory management.

As the business relationship continues to grow, it may be important to establish a regular review of cadence with scheduled assessments of performance metrics.

Performance efficiencies will enable organisations to staying ahead in a world that never stand still.

Inventory can easily shift from a liability to a competitive edge that drives business growth. The model is often conceived as a dream for organisations, bringing a string of joy and wonder in equal measure.

Nyika is a Supply Chain practitioner based in Harare, Zimbabwe. — [email protected].