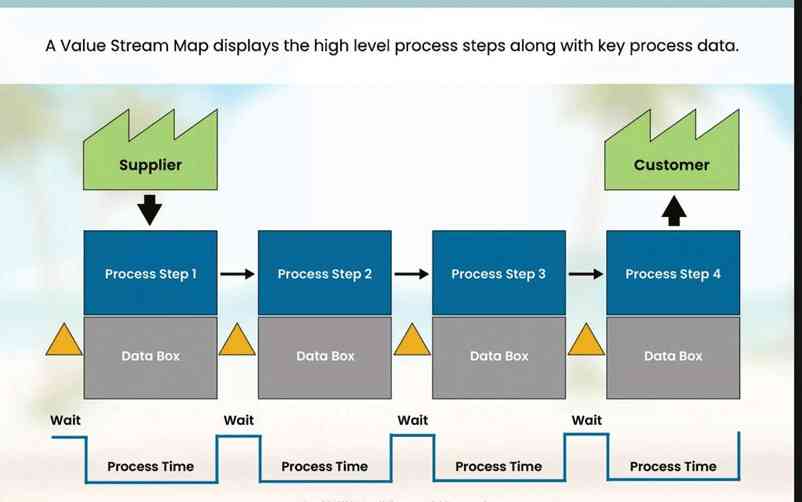

The best-in-class supply chain professionals don’t react to the future. They prepare for it and shape it. In today’s world, change is no longer a season. It is the climate. Supply chains will be much stronger, more sustainable and scalable when procurement professionals lock their arms together to continuously prepare for change. It is no longer enough to just join the conversation; lasting advantage belongs to those who shape the change in a world where yesterday’s expertise can become today’s blind spot. Value stream mapping uses the current, ideal, and future trends as lenses to bring sharp focus on value addition initiatives with a view to make things better. Value stream mapping is a lean management technique that visualises the flow of materials and information necessary for improving the delivery of products and or services. It is a visual management tool relied upon to map all the physical and information flows within the production system. Process mapping seeks to provide a bird’s eye view of the entire system, pinpointing either value-adding or non-value-adding activities. The value stream mapping process will allow procurement professionals to illustrate, analyse, design and optimise supply chain workflow processes for the production of a product from the beginning to the end. The mapping process will analyse the stages of making a product with a singular view to find the high-value stages and wasteful areas. Being a visual representation of the organisation’s production process, management will be in a position to pinpoint areas of backlog, stagnancy and waste. The idea is to examine the value stream with picky eyes to diagnose areas of waste and overprocessing. Professors will often write that “there is nothing so useless as doing efficiently that which is not to be done at all”. Value stream mapping will bring a fresh perspective that will assist supply chain professionals to challenge the status quo and implement innovative solutions. That will then assist in having a holistic understanding of how value flows through the ecosystem, providing a shared understanding of the value stream. Such an activity will project a clear representation of the current status of the business processes as the starting point for a holistic analysis of the value stream. For supply chain professionals, value stream mapping will enhance further learning about the nuances of each supply chain, pin-pointing areas where resources may be unnecessarily expended, leading to more informed decision-making. This very important management tool will be relied upon to carry out an industry depth analysis of current processes with a singular focus of identifying possibilities for continuous improvement in a highly-fluid business environment. The resultant changes could include the introduction of novel processes, the elimination of unnecessary activities, the reorganisation of functional departments, the introduction of new technologies and investment in management development. Insights from value stream mapping will form the basis for coming up with a roadmap for continuous improvement and adaptability. Using the value stream mapping concept, organisations will be in a position to produce a comprehensive work process flow diagram that shows every stage of the processes from “order-to-cash, procure-to-pay, plan-to-produce, plan-to-inventory forecast to monitor”. The concept will serve as a strategic lever to precisely optimise supply chain process flows in a business. It involves creating a visual map of the current value stream, with details about each activity, including the time required, wait times, inventory and more. The value stream mapping management concept is also key for the identification of waste. The process can be used to identify bottlenecks, inefficiencies and redundant steps, thereby conducting a waste identification exercise in every aspect of the value stream. Getting rid of waste is a means to an end of adding value. Waste ordinarily comes in many forms and types such as producing too much or too early, or it can arise out of overstocking. It can emanate from unnecessary transportation of raw materials when they are not yet due, it can arise through errors, defects and scrap. Waste could also emanate from ideal time between steps, adding features or steps that customers don’t value, excess stock that ties up capital, redundant employee movements and errors requiring rework. The waste reduction initiatives are therefore designed to streamline operations and ensure there is alignment with customer expectations to deliver quality products on time. With the potential elimination of waste and inefficiencies in the production value chain, supply chain professionals will be better positioned to reduce the amount of energy consumption, reduce scrap and rework, which will result in improved production equipment utilisation. By considering various approaches, such as process simplification, automation or reallocation of resources, top management will be fully aware that designing the future state of a supply chain is just as important as understanding the current state. Value stream mapping also encompasses the creation of a visual representation of the current state of the value stream and its future state. This process often tends to be cyclical. The current state of the value stream mapping will be designed and critically analysed to find out imperfections, if any. The current state map serves as a baseline against which future improvements can be measured. Whenever you reach your future state, it automatically becomes your current state, so there is always room for more improvements. The more you improve, the better the results you will achieve from the process. It will therefore allow supply chain professionals to visualise, analyse and improve their core processes. Supply chain professionals across all verticals are fully aware that it is now a strategic imperative to embrace the transformative power of value stream mapping given its capacity to unlock new levels of flexibility and agility. Benefits of value stream mapping often comes in many forms. Value stream mapping processes will benefit supply chains by identifying idle production machinery or underutilised staff members in the system. This increased visibility will eliminate delays and lags in the production system. In healthcare, it is common knowledge that any delays in patient waiting time could potentially result in serious fatalities. Value stream mapping in hospitals can create a map that clearly identifies all important points a patient will be required to go through from point of entry to point of departure. Hospitals can analyse patient flow from admission to discharge, pinpointing bottlenecks that may prolong wait times or unnecessarily complicate processes. This analysis not only improves operational efficiency, but also boosts patient recovery levels. The critical points of potential suboptimal performance that will likely slow down the entire value stream will also be noted with a view to improve them for the better. Value stream mapping will also assist in the reduction of lead times. Increasing on-time delivery can potentially improve customer satisfaction, resulting in cost reduction through reduced returns, increase in sales and improved customer retention. Value stream mapping will assist in the identification of areas where production wait times can be reduced in between production stages. Another often identified benefit of value stream mapping relates to sustainability. By incorporating sustainability considerations into value stream mapping, organisations can drive continuous improvements while contributing to a more sustainable future. When evaluating potential improvement opportunities, your team may also consider other factors such as safety, supplier diversity, reduction of the carbon footprint as well as quality and environmental impact.Value stream mapping is also a proactive approach; organisations can anticipate supply chain disruptions and develop solutions for customers before they are affected or inconvenienced. It goes beyond just looking at individual customer pain points, but focusses on the entire value stream. Process optimisation is viewed through the customer’s point of view. It will be time to set aside internal sectional interests and priorities will be solely focussed on the interests of customers. Nyika is a supply chain practitioner based in Harare. — [email protected].. They prepare for it and shape it. In today’s world, change is no longer a season. It is the climate. Supply chains will be much stronger, more sustainable and scalable when procurement professionals lock their arms together to continuously prepare for change. It is no longer enough to just join the conversation; lasting advantage belongs to those who shape the change in a world where yesterday’s expertise can become today’s blind spot. Value stream mapping uses the current, ideal, and future trends as lenses to bring sharp focus on value addition initiatives with a view to make things better. Value stream mapping is a lean management technique that visualises the flow of materials and information necessary for improving the delivery of products and or services. It is a visual management tool relied upon to map all the physical and information flows within the production system. Process mapping seeks to provide a bird’s eye view of the entire system, pinpointing either value-adding or non-value-adding activities. The value stream mapping process will allow procurement professionals to illustrate, analyse, design and optimise supply chain workflow processes for the production of a product from the beginning to the end. The mapping process will analyse the stages of making a product with a singular view to find the high-value stages and wasteful areas. Being a visual representation of the organisation’s production process, management will be in a position to pinpoint areas of backlog, stagnancy and waste. The idea is to examine the value stream with picky eyes to diagnose areas of waste and overprocessing. Professors will often write that “there is nothing so useless as doing efficiently that which is not to be done at all”. Value stream mapping will bring a fresh perspective that will assist supply chain professionals to challenge the status quo and implement innovative solutions. That will then assist in having a holistic understanding of how value flows through the ecosystem, providing a shared understanding of the value stream. Such an activity will project a clear representation of the current status of the business processes as the starting point for a holistic analysis of the value stream. For supply chain professionals, value stream mapping will enhance further learning about the nuances of each supply chain, pin-pointing areas where resources may be unnecessarily expended, leading to more informed decision-making. This very important management tool will be relied upon to carry out an industry depth analysis of current processes with a singular focus of identifying possibilities for continuous improvement in a highly-fluid business environment. The resultant changes could include the introduction of novel processes, the elimination of unnecessary activities, the reorganisation of functional departments, the introduction of new technologies and investment in management development. Insights from value stream mapping will form the basis for coming up with a roadmap for continuous improvement and adaptability. Using the value stream mapping concept, organisations will be in a position to produce a comprehensive work process flow diagram that shows every stage of the processes from “order-to-cash, procure-to-pay, plan-to-produce, plan-to-inventory forecast to monitor”. The concept will serve as a strategic lever to precisely optimise supply chain process flows in a business. It involves creating a visual map of the current value stream, with details about each activity, including the time required, wait times, inventory and more. The value stream mapping management concept is also key for the identification of waste. The process can be used to identify bottlenecks, inefficiencies and redundant steps, thereby conducting a waste identification exercise in every aspect of the value stream. Getting rid of waste is a means to an end of adding value. Waste ordinarily comes in many forms and types such as producing too much or too early, or it can arise out of overstocking. It can emanate from unnecessary transportation of raw materials when they are not yet due, it can arise through errors, defects and scrap. Waste could also emanate from ideal time between steps, adding features or steps that customers don’t value, excess stock that ties up capital, redundant employee movements and errors requiring rework. The waste reduction initiatives are therefore designed to streamline operations and ensure there is alignment with customer expectations to deliver quality products on time. With the potential elimination of waste and inefficiencies in the production value chain, supply chain professionals will be better positioned to reduce the amount of energy consumption, reduce scrap and rework, which will result in improved production equipment utilisation. By considering various approaches, such as process simplification, automation or reallocation of resources, top management will be fully aware that designing the future state of a supply chain is just as important as understanding the current state. Value stream mapping also encompasses the creation of a visual representation of the current state of the value stream and its future state. This process often tends to be cyclical. The current state of the value stream mapping will be designed and critically analysed to find out imperfections, if any. The current state map serves as a baseline against which future improvements can be measured. Whenever you reach your future state, it automatically becomes your current state, so there is always room for more improvements. The more you improve, the better the results you will achieve from the process. It will therefore allow supply chain professionals to visualise, analyse and improve their core processes. Supply chain professionals across all verticals are fully aware that it is now a strategic imperative to embrace the transformative power of value stream mapping given its capacity to unlock new levels of flexibility and agility. Benefits of value stream mapping often comes in many forms. Value stream mapping processes will benefit supply chains by identifying idle production machinery or underutilised staff members in the system. This increased visibility will eliminate delays and lags in the production system. In healthcare, it is common knowledge that any delays in patient waiting time could potentially result in serious fatalities. Value stream mapping in hospitals can create a map that clearly identifies all important points a patient will be required to go through from point of entry to point of departure. Hospitals can analyse patient flow from admission to discharge, pinpointing bottlenecks that may prolong wait times or unnecessarily complicate processes. This analysis not only improves operational efficiency, but also boosts patient recovery levels. The critical points of potential suboptimal performance that will likely slow down the entire value stream will also be noted with a view to improve them for the better. Value stream mapping will also assist in the reduction of lead times. Increasing on-time delivery can potentially improve customer satisfaction, resulting in cost reduction through reduced returns, increase in sales and improved customer retention. Value stream mapping will assist in the identification of areas where production wait times can be reduced in between production stages. Another often identified benefit of value stream mapping relates to sustainability. By incorporating sustainability considerations into value stream mapping, organisations can drive continuous improvements while contributing to a more sustainable future. When evaluating potential improvement opportunities, your team may also consider other factors such as safety, supplier diversity, reduction of the carbon footprint as well as quality and environmental impact.Value stream mapping is also a proactive approach; organisations can anticipate supply chain disruptions and develop solutions for customers before they are affected or inconvenienced. It goes beyond just looking at individual customer pain points, but focusses on the entire value stream. Process optimisation is viewed through the customer’s point of view. It will be time to set aside internal sectional interests and priorities will be solely focussed on the interests of customers. Nyika is a supply chain practitioner based in Harare. — [email protected].